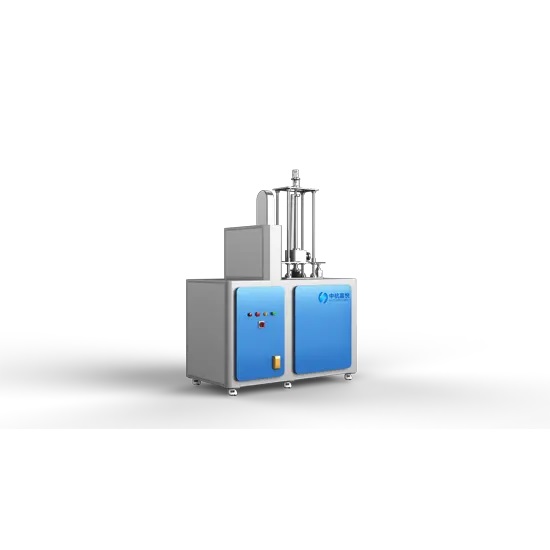

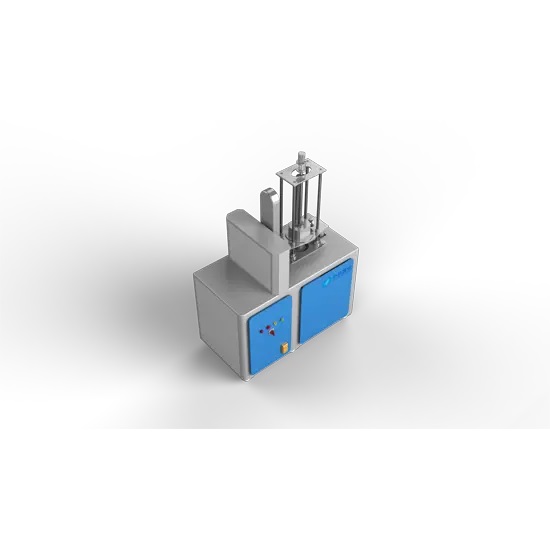

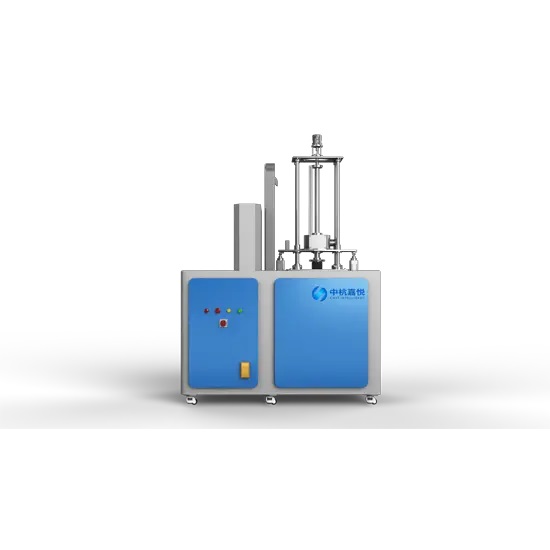

In advanced material science and industrial research, viscosity measurement plays a crucial role in determining the properties of fluids, melts, and new material composites. Traditional viscometers are not equipped to handle extreme environments where both high temperature and vacuum conditions are required. This is where a high temp vacuum viscosity meter becomes indispensable. By allowing precise monitoring of fluid behavior under controlled high-temperature and vacuum environments, researchers can obtain reliable data that reflects real-world industrial applications. Companies like CHJT have focused on the integration of intelligent control technologies with innovative designs, enabling their equipment to serve industries that demand extreme accuracy and stability.

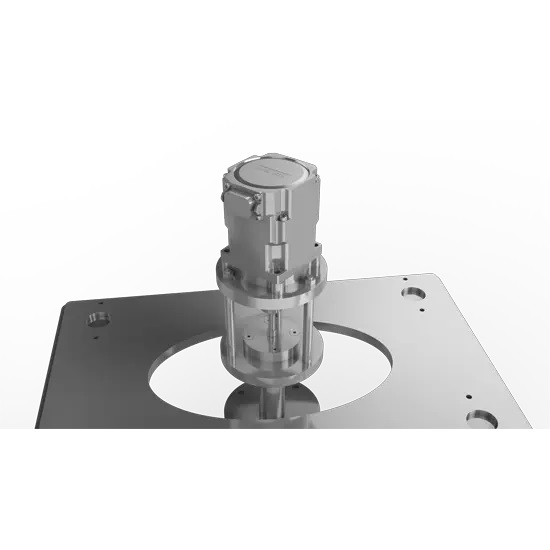

One of the primary advantages of a high temp vacuum viscosity meter lies in its ability to simulate harsh operating environments. It can measure viscosity in molten states without contamination, ensuring data integrity. Unlike conventional devices, these instruments integrate advanced automation, IoT-based control, and temperature field simulation to achieve highly accurate measurements. The system's stability allows researchers to test new materials under controlled vacuum pressure and elevated temperatures, which is critical in sectors like aerospace, metallurgy, and advanced ceramics. With CHJT's expertise in high-temperature intelligent equipment, such meters combine innovation with practical usability, making them valuable assets in both laboratory and industrial settings.

While both conventional viscometers and high-temperature vacuum systems measure viscosity, their operational differences are significant. The following table outlines some of the essential contrasts:

Aspect | High Temp Vacuum Viscosity Meter | Conventional Viscometer |

Operating Environment | Functions under high temperature and vacuum | Limited to standard temperature and pressure |

Accuracy in Extreme Cases | High precision in molten and volatile conditions | Less reliable under non-standard environments |

Contamination Risk | Minimal due to vacuum isolation | Higher due to open exposure |

Application Range | Advanced materials, aerospace, metallurgy | General laboratory and industrial fluids |

Control Technology | IoT-enabled, automated temperature/stress control | Manual or semi-automated functions |

This comparison highlights the unique benefits of high-temperature vacuum technology, making it clear why researchers and manufacturers working with next-generation materials rely on such advanced systems.

The development of modern high-temperature viscosity equipment has gone beyond mechanical precision to incorporate advanced computational and control technologies. Today's high temp vacuum viscosity meter often integrates stress simulations, automated monitoring, and real-time data collection, which enhances both accuracy and efficiency. The ability to synchronize temperature fields with vacuum control enables a more holistic understanding of material performance. This level of innovation reflects the philosophy of CHJT, where the design of equipment goes hand in hand with the evolving demands of industrial processes, ensuring that new materials can be tested under conditions closely resembling their operational environments.

High-temperature vacuum viscometers are not only laboratory tools but also essential for industries pushing the boundaries of new materials. They are widely applied in the study of alloys, composites, and advanced ceramics where understanding viscosity under extreme heat is critical for predicting performance. In aerospace engineering, viscosity data can guide the development of heat-resistant materials, while in metallurgy, it aids in improving smelting and casting processes. By bridging research and real-world application, instruments like those provided by CHJT contribute to the continuous progress of high-tech industries and advanced material development.