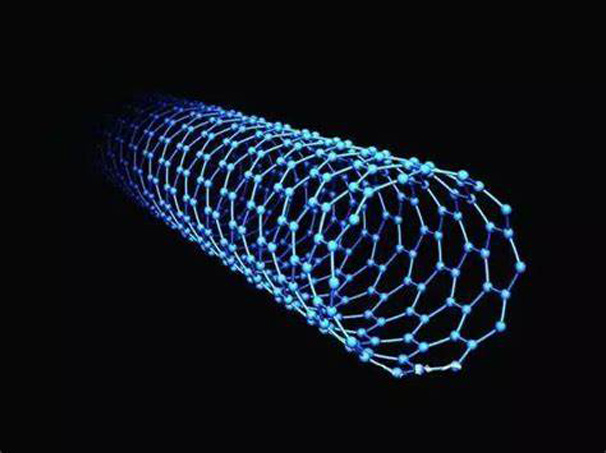

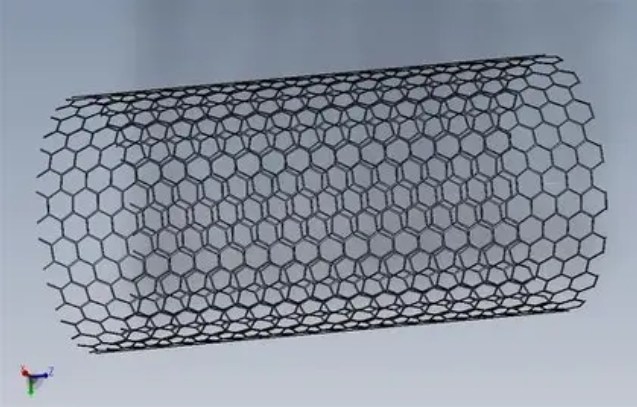

Single-walled carbon nanotubes (SWCNTs), renowned for their exceptional electrical, mechanical, and thermal properties, are often dubbed the "crown jewel of nanomaterials."

Yet in practice, achieving high purity is commonly equated with high difficulty due to narrow process windows, unstable equipment performance, and complex reaction environments — many enterprises find themselves stuck between lab success and industrial scalability.

CHJT’s floating-bed CVD SWCNT growth system breaks through these barriers, enabling a reliable path from R&D to industrial-scale production.

| Method | Product Type | Purity | Controllability | Energy Use |

| Arc Discharge | Mainly multi-wall | Low | Poor | High |

| Laser Ablation | Mainly single-wall | High | Excellent | High |

| Solid-State Pyrolysis | Low SWCNT yield | Medium | Poor | Medium |

| CVD | Single/Multi-wall | >90% | Strong | Low |

Key Advantages of CVD:

Low energy consumption: Optimized thermal design ensures high efficiency.

Scalability: Seamless transition from lab → pilot→ mass production.

High yield & repeatability: Stable thermal field and catalytic control deliver ≥90% SWCNT purity with minimal impurities.

Excellent batch consistency: ±3°C thermal control ensures repeatable performance.

Scalable output: Daily yield per production line can reach kilogram-level.

Driven by growing demand from the energy storage industry, floating-bed CVD technology has been validated by several top-tier domestic battery and materials companies. Their increasing output needs have also spurred continuous upgrades of our systems.

CHJT’s SWCNT production systems are backed by proprietary patents and offer a full-stack solution from R&D to industrial-scale output. With upgrades from horizontal to vertical orientation and from small to large reactor tubes, CHJT offers unmatched flexibility for labs, pilot plants, and full-scale factories.

Customizable scale: Multi-diameter and multi-tube combinations for flexible production planning. Large-diameter systems enable high-throughput output.

Continuous operation: Real-time discharge without furnace shutdown — a leap toward industrial continuity.

>20% carbon conversion efficiency, reducing raw gas cost.

>90% SWCNT ratio, minimal amorphous carbon, easing downstream purification.

High G/D ratio, excellent thermal stability, fewer structural defects.

Efficient gas mixing & preheating, improving decomposition efficiency.

Closed-loop hydrogen system: reduces gas waste and lowers cost.

Full-scope safety: Explosion-proof design, real-time monitoring, multi-level safety controls.

Flexible catalyst injection: Supports various catalyst types and feeding modes.

As a fully IP-protected, third-generation system, our single-walled carbon nanotube furnace ensures a key competitive edge for our clients. The successful adoption of the single-walled carbon nanotube furnace by leaders in energy and advanced manufacturing has enabled them to achieve a full production cycle, from delivery to stable mass output.

CHJT’s years of expertise in CVD have turned what was once a lab-intensive craft into a standardized, modular, and scalable engineering solution.

We are not just innovating inside research labs — we are delivering industrial-grade SWCNT production lines with real-world reliability. Moving forward, we will continue upgrading our intelligent equipment and expanding capacity, working hand-in-hand with researchers and enterprises to unlock the vast potential of carbon nanomaterials.

Together, we’re reshaping the global frontier of advanced materials.