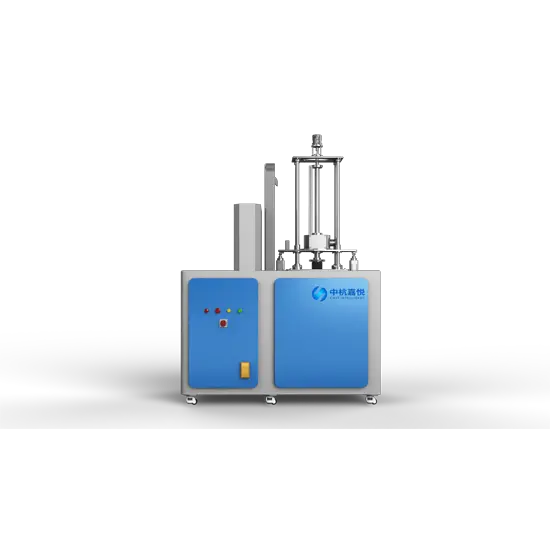

A high temperature vacuum viscosity meter is a specialized instrument designed to measure the viscosity of melts, slurries, or other fluid materials under high-temperature and vacuum conditions—the core functionality that defines the high temperature vacuum viscosity meter. Unlike traditional viscometers, it provides accurate viscosity measurements in extreme thermal and low-pressure environments. The high temp vacuum viscosity meter is widely used in industries such as optical glass manufacturing, ceramics, electronic slurry development, and metal smelting. It is especially suited for applications requiring precise viscosity monitoring under high heat and vacuum, offering essential data for scientific research, quality assurance, and process optimization.

This type of high temp vacuum viscosity meter must be engineered to withstand extreme heat while also operating reliably in low-pressure environments. This dual capability gives it a distinct advantage in niche applications such as molten metal analysis, coal gasification, and viscosity testing of protective slags.

Our high temperature vacuum viscosity meter operates based on the classical rotational viscometry method. This high temperature vacuum viscosity meter involves immersing a rotor in the test fluid and rotating it at a controlled speed. As the rotor spins, it encounters resistance from the fluid — a force directly related to the fluid's viscosity.

In high-temperature and vacuum conditions, the rotor continues to rotate within the fluid, where molecular interactions produce internal friction. This inter-layer resistance is proportional to the fluid's viscosity. By measuring the torque required to maintain rotor rotation, the high temperature vacuum viscosity meter calculates the fluid's viscosity value. Unlike conventional high-temperature viscometers, the high temperature vacuum viscosity meter ensures precise results even under vacuum, making it indispensable for materials whose viscosity cannot be accurately measured under standard atmospheric conditions.

This principle allows the high temp vacuum viscosity meter to excel in high-performance applications, including specialty glass production, advanced ceramics, metal refining, and fuel gasification. High temp vacuum viscosity meter provides critical insights into material behavior, enabling precise control over product quality and manufacturing processes. This level of performance is a hallmark of a modern high-temperature viscometer, with instruments from brands like CHJT trusted to deliver accuracy in challenging industrial environments.

To further improve high-temperature control, CHJT's debinding furnaces integrate Kanthal resistance wires as heating elements, combined with intelligent temperature control, SCR (silicon-controlled rectifier) regulation, and high-precision feedback systems. The high temp vacuum viscosity meter double-shell design features an air-cooling mechanism that regulates the external surface temperature, perfectly supporting the demanding conditions of high-temperature viscosity testing.

With these integrated systems, CHJT Intelligent delivers robust and reliable solutions for advanced materials testing, providing a strong technological foundation for both laboratory research and industrial-scale production. By utilizing an advanced high temperature vacuum viscosity meter, researchers can effectively characterize the flow behavior of specialty alloys and glass without the risk of oxidation, leading to more consistent results in sensitive material development.