On August 15, CHJT launched its Ansys training series—the first two-day session set the stage for seven more to follow.

While appearing as an internal upskilling program, this initiative reflects a bigger vision: building an integrated platform connecting theory, testing, and manufacturing. It’s not a standalone effort—it’s part of a structured system where theory fuels innovation.

Through systematic training in thermal analysis, finite element modeling, and simulation, teams gain more than software skills. They learn to guide real-world decisions with scientific models, iterate safely in virtual environments, and get it right the first time.

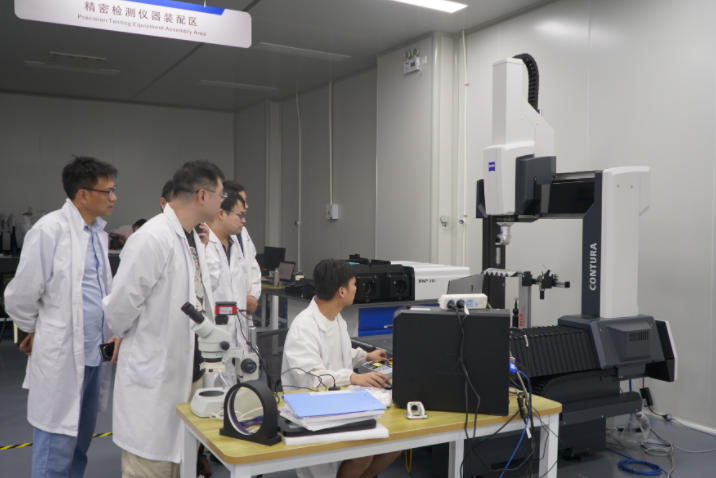

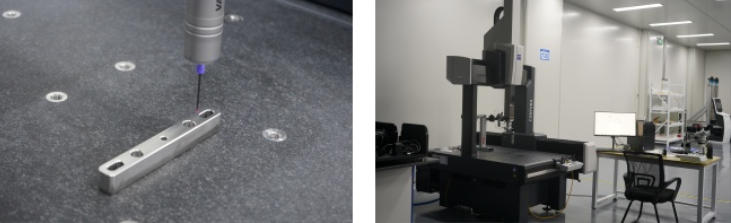

Theories must be proven. With CMM and ICP-OES, we ensure precision in geometry and composition. Atomic force microscopy and XRD further analyze surface morphology, crystal structures, and multi-scale properties—building a full-spectrum verification system from dimensions to material makeup.

This closes the loop between theory and testing, validating every simulation at micron and elemental levels.

Manufacturing turns vision into value.

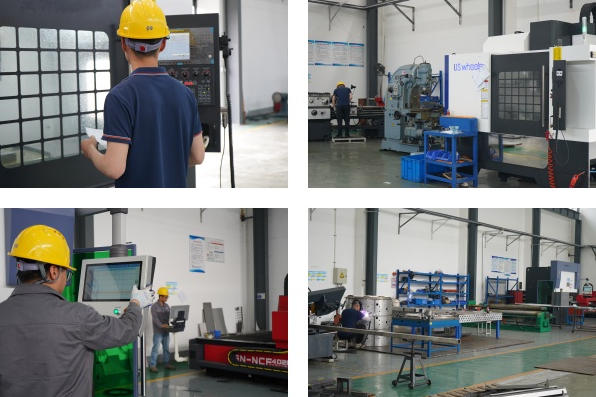

CHJT is automating tomorrow:

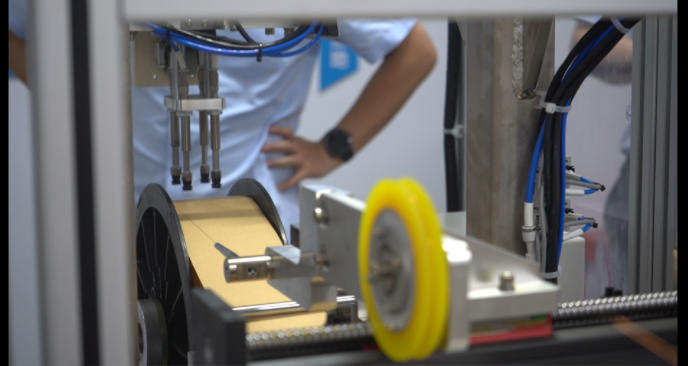

Automated wire spooling: continuous winding, interleaving, and packaging;

Vacuum furnace robots: integrated loading for fully unmanned “lights-out” production;

Machining centers: high-precision manufacturing of core components.

These are glimpses of a system built to turn R&D into reality—fast and reliably.

One Cohesive System

Theory, testing, and manufacturing connect through continuous data and feedback:

Forward flow: Theory → Design → Validation → Production

We’re building a modern R&D ecosystem—powered by data, driven by models, enabled by software, and led by people.

Training, testing, and automation are only the beginning. Behind them stands an integrated platform that links design, verification, and manufacturing.

CHJT is committed to deepening this integration—evolving from manufacturing to smart manufacturing, and powering the future of advanced material equipment.

—CHJT: Where Theory Meets Making