Amid the global wave of energy transition, a new nuclear technology—neither uranium-based nor oil-based—is quietly emerging: the Thorium-based Molten Salt Reactor (TMSR).

This represents not only a breakthrough in energy technology but also the potential to ignite a new industrial revolution centered on thorium resources.

Whoever pioneers this field will seize the initiative in future clean energy and advanced materials.

CHJT, with its strong R&D heritage and equipment manufacturing expertise, is becoming a key player in this transformation.

Recently, the 2 MW liquid-fueled Thorium-based Molten Salt Experimental Reactor, led by the Shanghai Institute of Applied Physics, Chinese Academy of Sciences (CAS), successfully achieved thorium-to-uranium fuel breeding and obtained the world’s first operational data on thorium fuel irradiation. This milestone not only reinforces China’s leading position in molten salt reactor technology but also signals the emergence of a new energy industry centered on thorium.

China possesses 1.3–1.4 million tons of thorium reserves, enough to support energy supply for thousands of years. TMSR aligns perfectly with this resource endowment, offering a new pathway to energy security. With the localization rate of core materials and equipment continuously rising, a complete industrial chain around TMSR is taking shape—a new road is accelerating its formation.

Resource Advantage: China's rich thorium reserves make the development of TMSR and thorium-uranium fuel a closed-cycle crucial for national energy security.

Technological Leap: As a Generation IV advanced nuclear system, TMSR uses high-temperature molten salt as a coolant, offering inherent safety, air-cooling capability, atmospheric pressure operation, and high-temperature output. Its liquid fuel design enables online refueling, continuous power generation, higher fuel utilization, and significantly reduced long-lived radioactive waste.

Industrial Restructuring: TMSR is not just a power plant—it integrates upstream mining, midstream materials and equipment manufacturing, and downstream energy applications. This includes thorium mining, purification, fuel conversion, nuclear material and equipment production, and system integration. With over 90% localization in core equipment, a complete industrial ecosystem is forming—spanning from thorium mining to clean power generation, high-temperature hydrogen production, heating, medical isotope production, and new material synthesis.

Upstream: Thorium resource acquisition and conversion, including mining, extraction, and in-reactor conversion of thorium-232 into fissile uranium-233—a “self-sustaining” fuel cycle.

Midstream: Core equipment and system integration, involving specialized alloys (e.g., nickel-based alloys), nuclear graphite, molten salt materials, pumps, heat exchangers, loop systems, and analytical instruments. Over 90% of the experimental reactor’s components are domestically produced, ensuring a controllable supply chain.

Downstream: Diversified applications in energy and materials—baseload power generation, high-temperature hydrogen production, industrial heat supply, medical isotope production, and advanced material synthesis.

News of the successful thorium-uranium conversion has sparked strong market interest. Related nuclear equipment suppliers have seen significant stock gains, reflecting investor recognition of TMSR’s disruptive potential and the new industrial opportunities it represents.

CHJT’s founding team includes members from the national TMSR R&D team, giving the company deep insight into the technology, process challenges, and industrial requirements. This enables a cohesive “Materials–Process–Equipment” integrated development strategy.

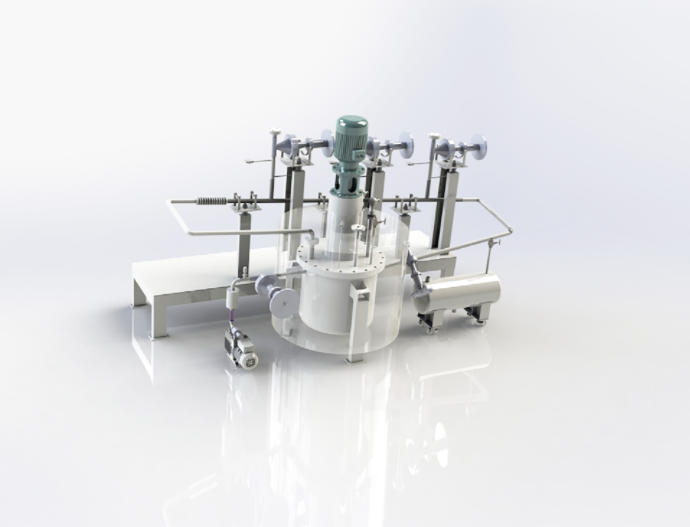

CHJT has developed integrated testers for high-temperature molten salts, accurately measuring density, surface tension, conductivity, and first crystallization temperature under an inert atmosphere. Instruments like high temp viscometers and thermal stability analyzers are already used in multiple TMSR research projects.

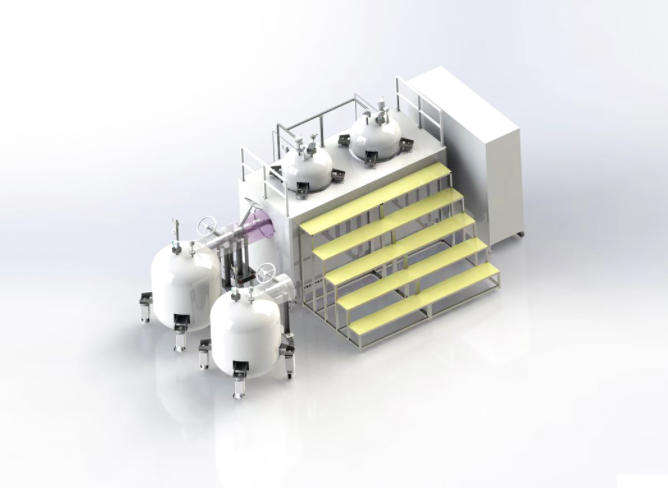

Leveraging experience in dry reprocessing, CHJT is applying these core strengths to molten salt preparation and purification—key for future high-temperature molten salt energy storage and reactor fuel supply.

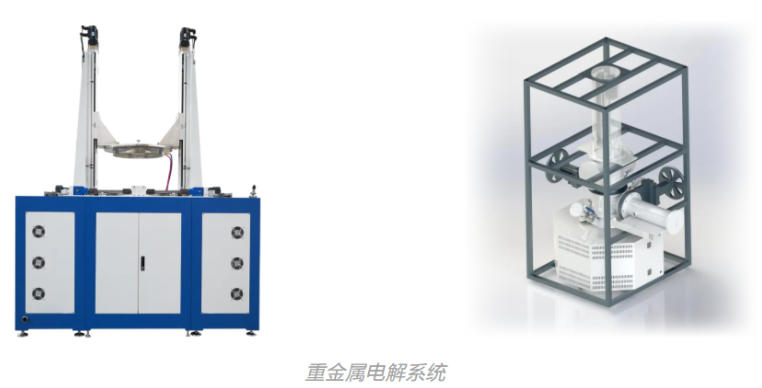

CHJT is developing and manufacturing critical experimental systems, including molten salt energy storage systems and corrosion and thermal-hydraulic test loops—essential for TMSR and derived applications, such as molten salt electrolysis.

Through these initiatives, CHJT has positioned itself across key nodes of the TMSR industrial chain—from material testing instruments to purification processes and system design. Its equipment is already used by leading institutions such as CAS, the China Institute of Atomic Energy, and the National University of Defense Technology, providing vital data support for national TMSR research.

Looking ahead, CHJT will continue to align with national energy strategy needs, deepening its layout in systematic technologies for efficient thorium resource utilization. By leveraging its strengths in equipment R&D and system integration, CHJT aims to provide more efficient and reliable core equipment and process solutions for the thorium utilization industry.

Through its trinity R&D model of “Materials–Process–Equipment,” CHJT is committed to becoming a key pillar in China’s future thorium resource utilization chain—contributing to the development of advanced nuclear fission energy.