Lithium is the "star metal" in the field of new energy, serving as a crucial material for both anodes and cathodes in lithium batteries. From smartphone batteries to electric vehicles, aerospace alloys to future nuclear fusion energy, lithium is everywhere.

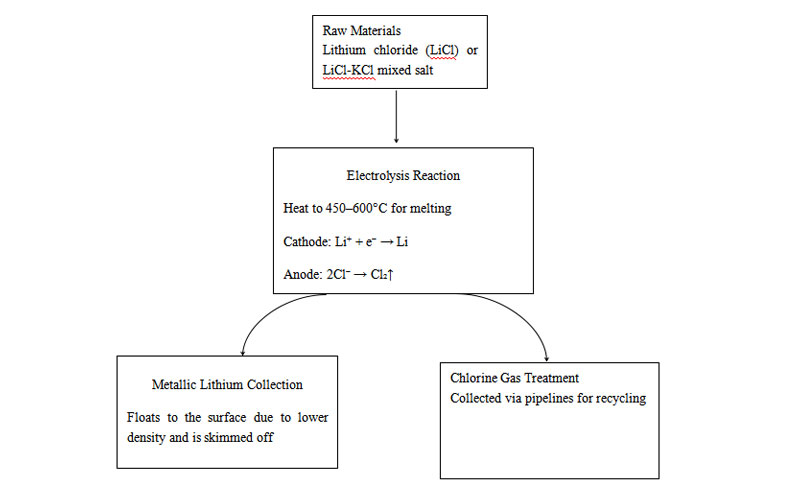

However, metallic lithium is highly reactive and does not exist in its pure form in nature—it is only found in minerals or salts. To obtain high-purity metallic lithium, electrolysis is virtually the only viable industrial method.

For highly reactive metals like lithium, sodium, and potassium, traditional smelting methods—such as carbothermal reduction—are ineffective because their oxides are too stable to be reduced by carbon or hydrogen.

Aqueous electrolysis is also unsuitable because water decomposes into hydrogen before the metal can be reduced. Thus, the only option is high-temperature electrolysis of molten salts.

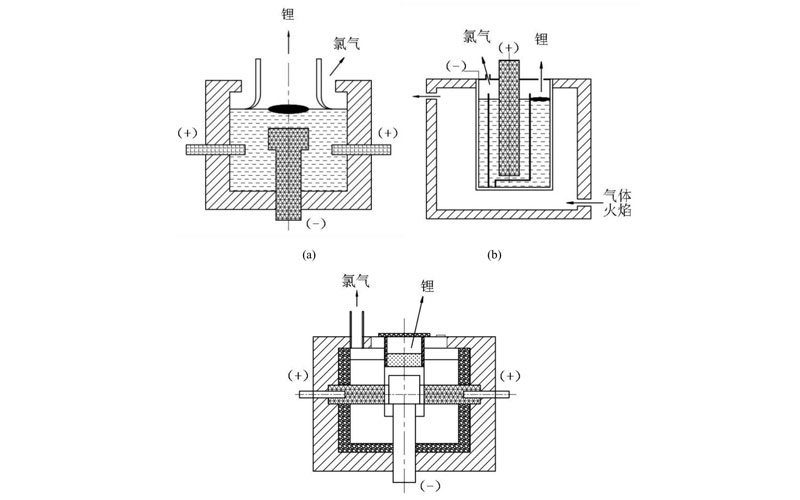

High-Temperature Corrosion: Molten salts severely corrode linings, anodes, and cathodes, requiring highly resistant materials.

High Energy Consumption: Maintaining molten salt temperatures demands significant heat, and electrolysis itself consumes substantial DC power. Solutions include improved insulation, heat recovery, and reduced cell voltage.

Byproduct Gas Handling: Toxic and corrosive chlorine gas requires multi-stage alkaline scrubbing to ensure safe emissions.

Strict Purity Requirements: Impurities (especially water and oxygen) reduce current efficiency and contaminate lithium, making pretreatment critical.

Higher Current Efficiency: Optimized electrode structures minimize lithium-chlorine recombination.

Lower Energy Consumption: Enhanced thermal insulation reduces heat loss.

Extended Lifespan: Corrosion-resistant linings.

Improved Safety: Robust chlorine collection and leak prevention systems.

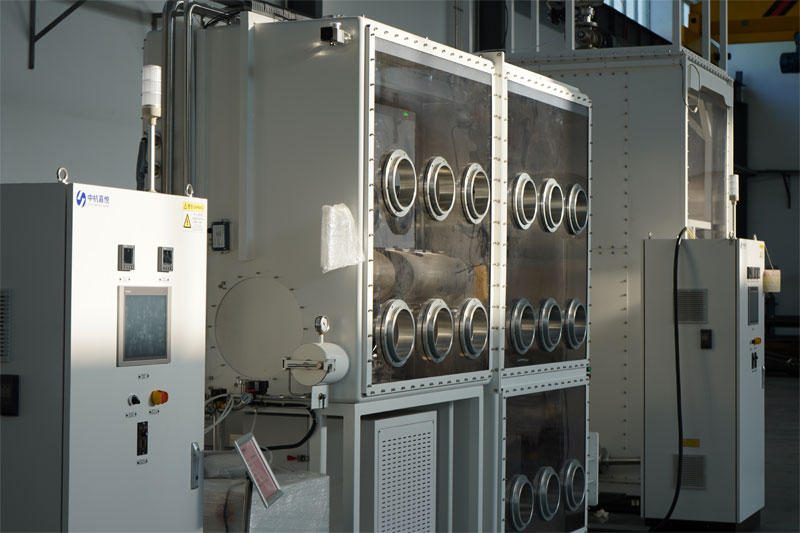

Hangzhou Jiayue Intelligence Technology Co., Ltd. ( CHJT) specializes in molten salt electrolysis equipment for light metals (Li, Na, Mg, Ca):

Dual-Zone Heating System: Independent temperature control (up to 1000°C, ±1°C) for electrolysis and collection zones, minimizing heat loss.

Modular Electrolysis: Customizable corrosion-resistant cells for lab-to-industrial scales (grams to kilograms), compatible with DC power or electrochemical workstations.

Inert Atmosphere Protection: Glovebox integration prevents moisture absorption; optional automated transfer modules boost efficiency.

Byproduct Management: Multi-stage alkaline scrubbers + spray cooling for safe chlorine handling.

Collection Upgrades: Traditional manual scooping or vacuum suction casting (with clog-resistant designs).

With AI advancements, CHJT is pioneering automation in lithium electrolysis.

Lithium electrolysis blends chemistry and engineering, demanding precision at every step—from ore to battery-grade metal. As the new energy sector grows, so does the need for efficient, safe, and stable electrolysis technology.CHJT remains committed to delivering cutting-edge solutions for academia and industry.